Buy Fluke 1587 T Insulation Multimeter | Powerpro Nigeria

Fluke 1587 T Insulation MultimeterSpecially designed for the telecom industry, the insulation multimeter is reliable and easy to use when working on motors, generators, cables, or switchgear. With a large backlight display and an auto-discharge of capacitive voltage, this meter provides maximum versatility for both troubleshooting and preventative maintenance.Fluke 1587...

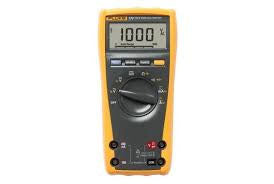

Fluke 1587 T Insulation Multimeter

Specially designed for the telecom industry, the insulation multimeter is reliable and easy to use when working on motors, generators, cables, or switchgear. With a large backlight display and an auto-discharge of capacitive voltage, this meter provides maximum versatility for both troubleshooting and preventative maintenance.

Fluke 1587 T Offers

Features

- True RMS voltage and current for accurate measurements

- Digital display counts of 6000

- Auto-range and manual range for easy testing

- Selectable filter for accurate voltage and frequency measurements on motor drives

- Special remote control probe for easy and safe measurements

- Auto-discharge of capacitive voltage for added user protection

- Live circuit detection prevents insulation test if voltage > 30 V is detected for added user protection

- Auto power off to save batteries

- Large display with backlight

- Input Alert to warn for incorrect connections

- Continuity

6 Tips for effective insulation testing

Disconnect any electronic devices like motor drives, PLC’s, transmitters, etc. before performing insulation testing. Electronics can be damaged by applying higher than normal voltage.

The effect of temperature should be considered - it is recommended that tests be performed at a standard conductor temperature of 20 °C (68 °F) or that a temperature baseline is established while compensating future readings by using a DMM with a probe or an infrared thermometer.

Select a test voltage appropriate for the insulation being tested. The objective is to stress the insulation but not to over-stress it. When in doubt, use a lower test voltage. It’s usually appropriate to test insulation at twice the voltage it normally sees: for example 460 V to 600 V rated equipment is often tested at 1000 V.

When using an insulation tester, leave the leads connected when you stop the test. The insulation tester can discharge any residual test voltage.

Conductors that are close to each other have a normal capacitance. This will cause an insulation resistance reading to start low and increase steadily until it stabilizes. This type of increase is normal, but if the reading jumps violently down and up again this indicates arcing.

Although the current is tightly limited, an insulation tester can generate sparks and minor but painful burns. The unexpected surprise can cause an operator to jerk away. As always, work away from live systems and use safe work practices when working overhead.

Fluke 1587 T Offers

Features

- True RMS voltage and current for accurate measurements

- Digital display counts of 6000

- Auto-range and manual range for easy testing

- Selectable filter for accurate voltage and frequency measurements on motor drives

- Special remote control probe for easy and safe measurements

- Auto-discharge of capacitive voltage for added user protection

- Live circuit detection prevents insulation test if voltage > 30 V is detected for added user protection

- Auto power off to save batteries

- Large display with backlight

- Input Alert to warn for incorrect connections

- Continuity

6 Tips for effective insulation testing

Disconnect any electronic devices like motor drives, PLC’s, transmitters, etc. before performing insulation testing. Electronics can be damaged by applying higher than normal voltage.

The effect of temperature should be considered - it is recommended that tests be performed at a standard conductor temperature of 20 °C (68 °F) or that a temperature baseline is established while compensating future readings by using a DMM with a probe or an infrared thermometer.

Select a test voltage appropriate for the insulation being tested. The objective is to stress the insulation but not to over-stress it. When in doubt, use a lower test voltage. It’s usually appropriate to test insulation at twice the voltage it normally sees: for example 460 V to 600 V rated equipment is often tested at 1000 V.

When using an insulation tester, leave the leads connected when you stop the test. The insulation tester can discharge any residual test voltage.

Conductors that are close to each other have a normal capacitance. This will cause an insulation resistance reading to start low and increase steadily until it stabilizes. This type of increase is normal, but if the reading jumps violently down and up again this indicates arcing.

Although the current is tightly limited, an insulation tester can generate sparks and minor but painful burns. The unexpected surprise can cause an operator to jerk away. As always, work away from live systems and use safe work practices when working overhead.

You can use this tab for adding shipping details, return policies and information or measurements etc.