For years, many plants employed "run to failure" maintenance, meaning no action was taken until machines stopped working. With this, maintenance costs and production losses were high. Then, many companies moved to preventive maintenance, where machines were serviced regardless of need. Often, this led to unnecessary repairs, and increased program costs. But in the last 30 years, the US Navy and multiple Fortune 500 companies have utilized condition-based maintenance. This involves measuring machines with methods like vibration analysis, and scheduling repairs only after a condition fault has been detected--not before, and not after.

Signs of machine health early on

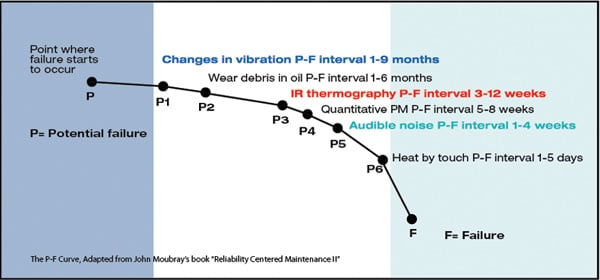

Several technologies aid in the measurement and analysis of machine health, including vibration testing and infrared thermography. The accompanying graph illustrates how changes can first be detected with vibration testing, and then with infrared thermography. It is only after these technologies that audible noise and heat may be felt, signifying a state of impending machine failure.

Benefits of early vibration testing include:

Predictability, providing maintenance personnel ample time to plan repairs and acquire components.

Improved safety by taking unreliable machinery offline before risk arises.

Fewer unexpected mishaps resulting in stoppages of production, boosting revenue.

Extended life of equipment and maintenance intervals, decreasing catastrophic system failures.

Enhanced assurance in maintenance plans, budgeting, and productivity projections.

Mechanics of vibration testing

A transducer captures vibration signals from bearing locations and sends them to a data collection device. It is paramount to note several things regarding the mechanics of vibration testing:

Rotating machinery generates a unique vibration signal over time, known as a time waveform.

This waveform contains valuable data about the machine.

Many vibration sources overlap and obscure one another, making it difficult to distinguish singular signals.

Frequency analysis done with a data collector simplifies the waveform into distinct, repetitive patterns.

Fast Fourier Transform (FFT) is an algorithm used in vibration testing tools that isolates individual signals.

The spectrum is a plot of these signals, showing amplitude vs. frequency.